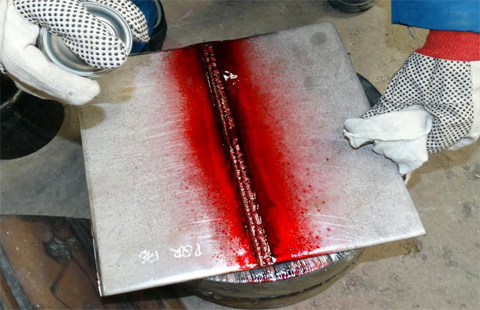

Dye Penetrant Inspection, also known as Penetrant Testing (PT), Liquid Penetrant Inspection (LPI) or Fluorescent Penetrant Inspection (FPI), Liquid penetrant is applied to the surface and left to soak, being drawn into any cracks by capillary action.

The excess penetrant is then removed and a developer applied to draw out the entrant from cracks, to enable

a visual inspection of any defects. Accurate interpretation is achieved by our seasoned NDT qualified Penetrant

Testing Inspectors, Dye Penetrant Inspection can be used on almost any non-porous material.

The types of defects that can be found with penetrant testing are:

- Rolled Products: Penetrant identifies anomalies (cracks, seams or laminations)

- Castings: cold shuts, hot tears, porosity, blowholes, or shrinkage.

- Forgings: Illuminating cracks, laps, or external bursts.

- Welds: To identify cracks, porosity, undercut, overlap, lack of fusion, or lack of penetration.

We have available more than 45 NDT technicians qualified to SNT Level II in Penetrant Testing (PT) in

compliance with SNT-TC-1A. As a minimum, all JCI penetrant testing inspection engineers have more than

one NDT qualification.